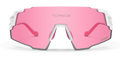

If you are a sea lover, you probably wear high-quality sunglasses to protect your eyes from sun glares that reflect from the sea. As it is known good pair of sunglasses can't be too cheap by considering all features they have: UV-protection, anti-fog and polarized, of course. But did you know that seawater can damage your eyewear if they don't have corrosion resistance? Let us tell you about this in detail.

What is seawater corrosion?

Seawater can seriously damage the eyewear lenses, especially if they are mirrored. The main reason is that coatings of the mirrored lenses are made of metal which ions in saltwater can accelerate the decomposition time of many metals, finishes, and varnishes. So coatings like anti-reflective coating need extra care as they are deeply affected by the decomposition characteristics of the water.

Ions in saltwater also cause the coatings to peel, the salt and sand in the water can scratch the lenses, so it's necessary to have special coatings on the sunglasses, which can prevent these things.

The lenses with resistance to seawater corrosion.

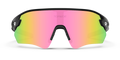

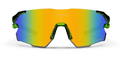

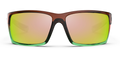

TOREGE anti-seawater lenses use a special coating process to make the coating film more stable in combination with the lens and can withstand the test of over 48H seawater immersion, effectively resisting weak acidic and alkaline water quality, and meeting the wearing needs at the seaside, etc.

A layer of SiO film is formed by vacuum electroplating on the surface of the lens, a layer of SiO2 film is formed by vacuum electroplating on this SiO film, and then a layer of anticorrosive film is formed by vacuum electroplating on the SiO2 film, and then a layer of SiO2 film is formed by vacuum electroplating on this anticorrosive film, and then a layer of SiO film, four layers of SiO2 film and four layers of anticorrosive film are formed alternately, which is to make nano-anti-seawater coated lenses. It has the advantages of corrosion resistance, no peeling in the case of seawater, and UV resistance.